|

|

This topic comprises 2 pages: 1 2

|

|

Author

|

Topic: Speaking of Failsafes

|

Paul Konen

Jedi Master Film Handler

Posts: 981

From: Frisco, TX. (North of Dallas)

Registered: Jun 99

|

posted 07-04-2000 10:04 PM

posted 07-04-2000 10:04 PM

At Cinemark, we are using FM-35 failsafes.Tonight, Patriot in our big house continued to payout on the floor for about 10 minutes before the UB for that side noticed it and stopped the show. We did not get a chance to look at the indicator led's for the failsafe to see what it was seeing at that time. It was interesting to see the film continue to spew onto the floor, running through the failsafe like nothing had happened. I think what happened though was the takeup arm was wavering back and forth like the LED was unstable (Christie AW-3's) and it eventually went all the way back and stopped. Paul.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

John Pytlak

Film God

Posts: 9987

From: Rochester, NY 14650-1922

Registered: Jan 2000

|

posted 07-05-2000 12:26 PM

posted 07-05-2000 12:26 PM

Just to clarify, since there are two "failsafe" threads going:There are two types of "failsafes", and BOTH should be used in automated platter situations: 1. A film break / run out detector, often combined with a cue detector. These are usually located just as the film exits the analog soundhead. The film runs past a motion detector (like the Component Engineering FM-35) or microswitch roller (e.g., Kelmar), which detects when the film stops moving or has broken. This type of detector is useful to shut things down after the film has run out, if the film is not being properly taken up, or if a film/splice breaks upstream. They help avert the disasters of a broken splice in the projector causing a film pile-up in the projector, or running a feature onto the floor if the takeup fails. 2. A tension-sensing failsafe. If the film jams in the platter, or if the film fails to feed properly, this device senses a buildup in tension and shuts down the projector before the film can damage anything. In their simplest form (e.g. AVASK unit), they are simply a spring-loaded roller that trips a microswitch when tension builds. Other units use a film carriage (often on the platter column) that is pulled up by excess tension, tripping a microswitch or sensor. Tension sensing failsafes that use a carriage usually allow enough slack to have the projector coast to a stop without damaging anything. Tension-sensing failsafes are essential equipment when using polyester film, because if the film fails to feed properly from the platter, the film will usually NOT break, but the tension buildup will stretch the film and often WILL break something else. ------------------

John P. Pytlak, Senior Technical Specialist

Worldwide Technical Services, Entertainment Imaging

Eastman Kodak Company

Research Labs, Building 69, Room 7419

Rochester, New York, 14650-1922 USA

Tel: 716-477-5325 Fax: 716-722-7243

E-Mail: john.pytlak@kodak.com

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brad Miller

Administrator

Posts: 17775

From: Plano, TX (36.2 miles NW of Rockwall)

Registered: May 99

|

posted 07-09-2000 03:36 PM

posted 07-09-2000 03:36 PM

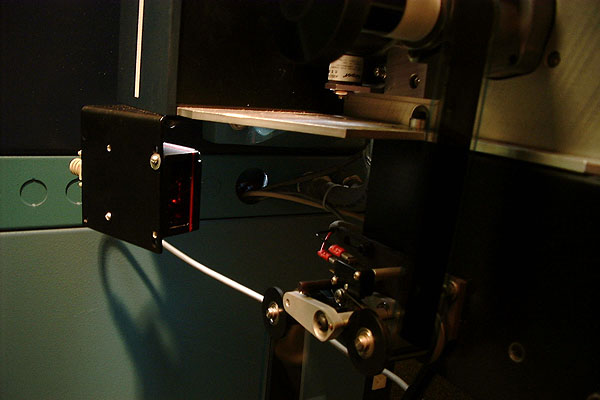

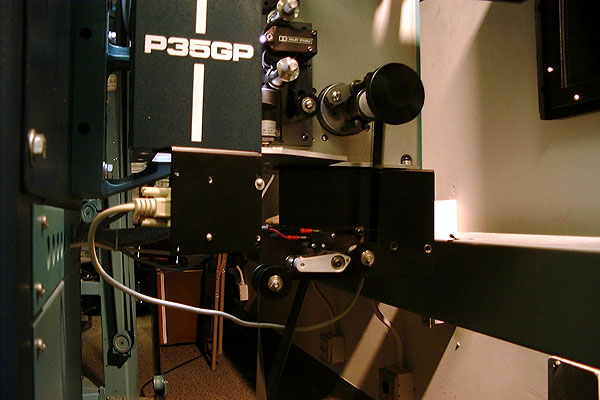

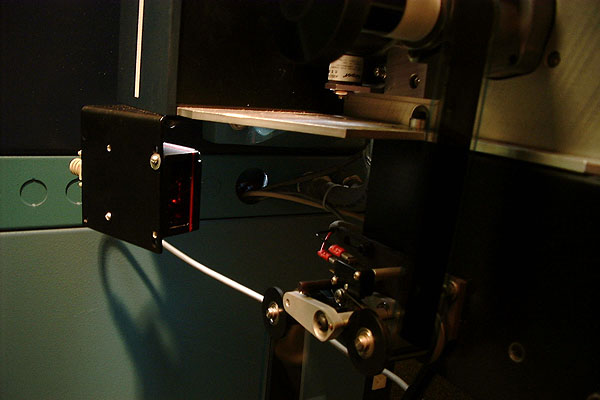

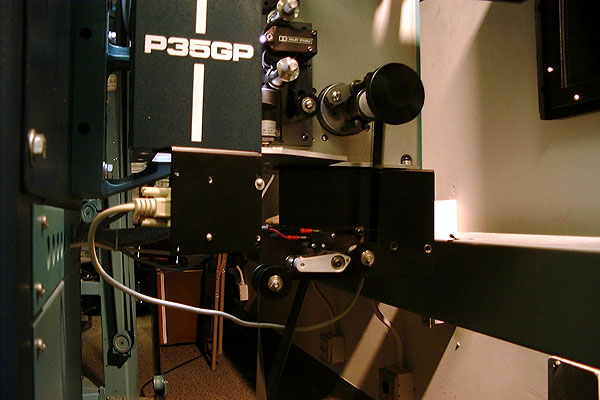

Ethan,That's Strong SPA-5 automation with upgraded failsafes (courtesy of UA). You've got the original "A" version of them which can only handle 4 cues, but does scan each bar code 5 times. The later versions which could read up to 99 bar code cues only scanned each cue one time, so hope it doesn't miss! This was installed into UA theaters courtesy of Gary Stanley's design, built by Kelmar. Later this was replaced with a visible light and at that point it was an incredibly efficient and reliable system. Basically the cues tell the automation what to do, not the other way around. My only beef was those HUGE cues which left something to be desired on the screen as they passed through. Here was my solution:

Basically I just modified the mounting bracket and had them set to scan the "S" edge of the SDDS track. It worked flawlessly and did not even shift the picture slightly as the cues passed. Tip: to anyone using the older "cream colored" scanner boxes, if you get "NT Audio Visual" blue mylar framing leader (extremely common), you can put your head up against the scanner and look at the film with your hand behind it and clearly see the "invisible" led light to check alignment without that horribly expensive viewer. (Note: you MUST put your hand behind the film where you will be looking.)

| IP: Logged

|

|

|

|

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 2 pages: 1 2

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic