|

|

|

|

Author

|

Topic: Film Tech Media Tips Needed

|

|

|

|

|

Brad Miller

Administrator

Posts: 17775

From: Plano, TX (36.2 miles NW of Rockwall)

Registered: May 99

|

posted 03-23-2002 05:53 AM

posted 03-23-2002 05:53 AM

James is on the right track. If the takeup core can spin with the thumbscrews tightened down, you need to go to a smaller core, or make a modification. Basically put there are 3 different sizes of cores in the field. Neumade/Big Sky...just a tad smaller than Kelmar

Kelmar...typical

Film-Tech...just a tad larger than Kelmar (plastic) Depending on a few things, but mostly the condition of your rubber inserts being used in the takeup shafts, you may need to use a certain type of core for takeup. I generally stay away from using the Neumade/Big Sky cores because they are so small that they are very difficult to get onto the takeup shaft and they do not loosen up well for proper rewinding of the media. If you have new rubber inserts (or some of the "skinnier" ones I've been seeing lately), you will have to either use the cardboard cores (preferably the Kelmar) or drop a washer at the base of the takeup shaft to allow the rubber to be compressed more. Once the rubber starts to wear (or if you use the washer trick), you will be able to switch to the plastic Film-Tech cores for takeup, at which point you will find the media rewinds smoother and easier. Just remember, if you use the washer trick, don't line up the media squarely on the takeup core when loading, for the entire shaft will be raised just a bit toward the operator. The best way to attach media to the takeup shaft is to hold back the supply roll with a finger to provide tension, and with the head end of the media, simply align the media so that there is no rippling/waving of the media between the idler roller and the takeup shaft. That will be a straight-shot alignment. P.S. Once you find a core that takes up properly, do not remove it. Just loosen the thumbscrews and pull the media off of the core backwards.

| IP: Logged

|

|

|

|

Brad Miller

Administrator

Posts: 17775

From: Plano, TX (36.2 miles NW of Rockwall)

Registered: May 99

|

posted 03-23-2002 06:52 AM

posted 03-23-2002 06:52 AM

I don't know what you could be doing wrong. I've had zero problems with the white media. The blue media was discontinued for a few reasons. The "blue" part of it raised the cost and people wanted more on the rolls, so the pretty color was abandoned in favor of very long rolls. Also we did get complaints that the blue made it "harder to see how dirty the pads were". I'm not sure if I completely agree with that, but there were plenty of people who felt that way.Remember the original theory was to provide enough for one pass on a roll and then rewind, per the FilmGuard instructions. That theory was quickly abandoned after we found out that different versions of the film cleaning machine run at different speeds. (A huge oops, which I ended up making good with many a theater who got rolls that were too short to run on their geared style cleaners.) Plus, people seem to be very happy with the extended length of the rolls we have been shipping for some time now. Most people cut them in halves or thirds to make double or triple the amount of rolls. We also discontinued the blue media because it was having rewind problems due to how thin and fragile it was, which made it much harder to rewind (hence my amazement you are having problems with the white). BTW, a tight or loose wind on media fabric makes no difference. Regardless, I'm going to need more specific details so I can figure out where your problem lies. Email me whatever specifics you can to start with and once we have figured out the problem we can post it back here in case someone else is having difficulty.

| IP: Logged

|

|

|

|

|

|

|

|

Brad Miller

Administrator

Posts: 17775

From: Plano, TX (36.2 miles NW of Rockwall)

Registered: May 99

|

posted 03-23-2002 12:49 PM

posted 03-23-2002 12:49 PM

A re-write of the instruction sheet is being worked on, for too many people are confusing the wordage "saturate the pads" to mean "dunk the pads into a cup filled with FilmGuard". The trick is to load up your pads onto the cleaner, secure the head end (yes, Magic tape works the best), then while you have the sprayer nozzle pressed up against the supply roll, squirt the pads down until they are saturated. Of course you should take a paper towel and wipe off any residual FG on the takeup core before you do this, but there's generally very little.If you have been saturating the pads before loading to your cleaner, then that's almost certainly your problem. If not, it may be something else (those rubber inserts don't last forever, and they may have just died on you).

| IP: Logged

|

|

Jason Black

Phenomenal Film Handler

Posts: 1723

From: Myrtle Beach, SC, USA

Registered: Nov 2000

|

posted 04-01-2002 02:46 AM

posted 04-01-2002 02:46 AM

Brad, and anyone else who might help...I rec'd the newer white media and began using it this past week. I noticed right away that I would have to 'shim' the supply roll at the base so the core would rest snugly against the "button cap". This due to the fact that I also have to wind my media backwards of the arrows, as due to the position of the mounting brackets on the trees.  Now, I have noticed that the lower supply and take up rolls actually begin to touch about the time the media is 1/2 way through the roll. What, if anything, can be done to prevent this from happening? Aside from, of course, relocating the mounting brackets on the trees. *This is beginning to become a favorable idea, however*

| IP: Logged

|

|

Brad Miller

Administrator

Posts: 17775

From: Plano, TX (36.2 miles NW of Rockwall)

Registered: May 99

|

posted 04-01-2002 02:59 AM

posted 04-01-2002 02:59 AM

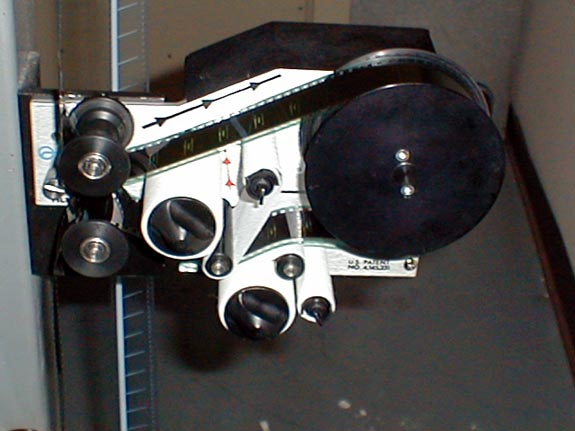

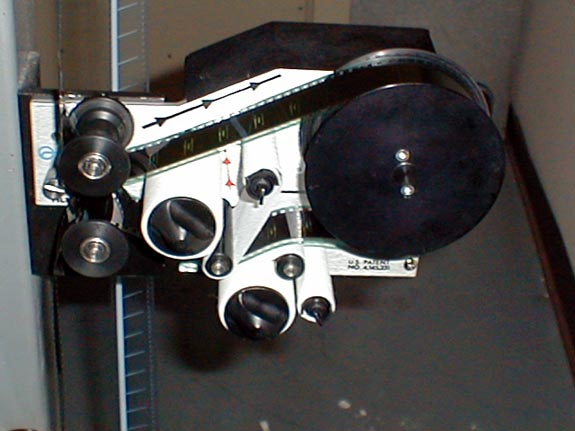

What do you mean you have to shim the supply roll at the base? I assume this means that because the film is running "backwards" through the cleaner that the rolls of media will unwind themselves during operation if there is not a drag on the supply cores, correct? This picture doesn't show your mount. Can you get a wider shot? What kind of platter is this mounted to? (Honestly, the real solution here is to fix your mount so you can use the machine the way it was designed to be used.) Yes, the lower rolls can touch mid roll due to the sheer amount of media we are loading onto the rolls. Why? The vast majority of people wanted huge rolls, so we are delivering for them. (I did speak to Kelmar about the possibilty of moving that lower takeup shaft over 1/2 inch to permit the use of even larger rolls and the response was favorable.) Anyway, if you are using FilmGuard with that media you really should consider cutting the rolls in half (or thirds) before use for the ideal level of application (plus you will get "two boxes for the price of one"). If you are using the pads dry, you can just cut off a couple of feet before loading the cleaner. Either way, you still get a better value. (New, more detailed instruction sheets with pictures will be shipping shortly with all FilmGuard kits which addreses various minor questions like this. Look for them.  ) )

| IP: Logged

|

|

Jason Black

Phenomenal Film Handler

Posts: 1723

From: Myrtle Beach, SC, USA

Registered: Nov 2000

|

posted 04-01-2002 09:30 PM

posted 04-01-2002 09:30 PM

Brad,You're right about he mounting brackets. I know that this is the only *real* solution, yet I was curious to see if the media rolls touching on the lower shafts were a common problem, or if I was just that dumb.

By shimming the roll, I meant I put a nylon washer on the lower part of the shaft in order to "push" the media up against the fastening "button". And yes, it would literally drag the media off the supply rolls were I not doing this. I did notice, however that the blue media could be shimmed on the top of the roll, at the button fastener, rather than placing a washer at the lower part of the shaft... hey, whatever works work, right? I would be in favor of having Kelmar space the lower shaft out as the top one is, so that you could go with an even bigger media roll if you so desired. The lentgh of the white ones now is just fine for me... And Thanks for the reply!

| IP: Logged

|

|

|

|

All times are Central (GMT -6:00)

|

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

)

)