|

|

This topic comprises 3 pages: 1 2 3

|

|

Author

|

Topic: Trouble with Brand New Strong Platters

|

Joe Redifer

You need a beating today

Posts: 12859

From: Denver, Colorado

Registered: May 99

|

posted 09-02-2002 01:35 AM

posted 09-02-2002 01:35 AM

I have 2 factory new Strong platters. I have had them for 3 weeks. They are A3 phase controls and were manufactured in May and July of this very year. When I first set them up they ran great. Payout was smooth. So smooth, in fact, that it seemed like the decks and film were standing still. But over the course of a few days the payout began to become unsmooth. The film drags around the brain, sometimes even 2 wraps thick, for the entire show. I retime each deck and everything is smooth again for a few days. But then they begin to drift again! The problem does not follow a particular brain.I do know that variac controlled platters are very nit-picky with the timing. Mess with the speed of one deck and you affect them all. But I have seen these things payout slower and slower over the course of my shift so I am sure that no one is tampering with them when I am not there. The platters need to be retimed once every 5 to 7 days it seems. Any suggestions on what I can do to make these things run smooth 100% of the time? I would like to stress again that these are brand new. I am ready to answer questions if you all need more info about the set up.

| IP: Logged

|

|

Paul G. Thompson

The Weenie Man

Posts: 4718

From: Mount Vernon WA USA

Registered: Nov 2000

|

posted 09-02-2002 03:56 AM

posted 09-02-2002 03:56 AM

Joe, are both A-3's doing this, or just one of them? If they are both doing it, I would look for a common cause. The only thing that would be common is the input AC power.Also, check the control rod from the elevator to the variac. If the jam nuts are loose, it could be doing some nasty adjustments to itself. Another thing to look at....where is the elevator riding when the pay-out falls behind, and where is it riding when the platter is running normally? You will see a change over the course of the movie. If it is favoring the timing hole in the mast, it is probably riding too high. I would recommend you verify the variac setting before you start to time your platters. Remember - you have two holes in the mast. A Threading hole, and a Timing hole. The Timing hole is the upper hole. I could be wrong on this, but when the elevator is resting on the bottom, the wiper on the variac should be about 50%. Would someone verify that setting, please? Be careful of your motor tracking. If it is set too heavy, the motors will require more current. This was also a common failure with the Christie Autowind I's and II's. It caused alot of module failures on those machines. The SCR in the A-3 phase controls might not like that, either. Never raise the elevator without turning off drive motor switches first. The surge current could damage the SCR's in the phase controls. I believe that if Strong's engineers did something about the inductive spike that could occur across the SCR's, the phase controls would last a very long time.

| IP: Logged

|

|

|

|

|

|

|

|

Paul G. Thompson

The Weenie Man

Posts: 4718

From: Mount Vernon WA USA

Registered: Nov 2000

|

posted 09-02-2002 01:47 PM

posted 09-02-2002 01:47 PM

An experiment I might try on mine.....I have one phase control that still works, and yes, it does fall behind especially near the end of the movie when the elevator rises.I might increase the size of the ballast resistor inside the motor can by a couple of Ohms. The resistor is a 25-watt 2 Ohms. This resistor is switched in series with the motor during the take-up mode. The elevator will ride lower if this resistor is electrically larger, hereby allowing more power to be applied to the pay-out motor so it won't fall behind. After it finally blows all the SCR's and is converted to micros as Mark describes, one can put 10 ohm 25-watt shunt resistor across the micro switch so the platter will not whip so badly. I tried that already, and it works to a degree. However, the resistor I used was not large enough in resistive value. It has to be large enough so the platter will not creap in the pay-out mode while the plunger is engaged in the threading hole. It will be a trade-off between variac settings, the resistor value and motor tracking pressure for it to work right. On a second thought, I think I will take a phase control unit and install it on a retro fitted micro-switch pay-out head on a CFS platter. The 10 ohm shunt resistor inside the motor, but I am not sure how the phase control will like that resistor. I'm gonna find out!!!!  So, off I go to Oak Harbor to snitch a brain for modification. The old orange POTTS and blue CFS platters used a set-up very similar to this. Check the schematic, and you will see..... As far as the Strong Digital platters are concerned, the jury is in. They have been out in the market for about 5 or 6 years now, and according to the feedback I have received, it is a very reliable machine. I will consider them in new construction.

| IP: Logged

|

|

|

|

|

|

Paul G. Thompson

The Weenie Man

Posts: 4718

From: Mount Vernon WA USA

Registered: Nov 2000

|

posted 09-02-2002 08:11 PM

posted 09-02-2002 08:11 PM

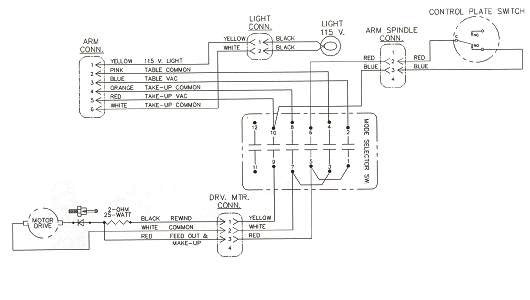

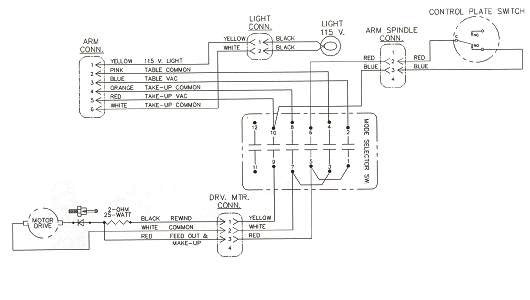

Steve, that is exactly what that resistor does. I explained that in my post, but perhaps it was not as clear as the way you explained it. Thank you for explaining it another way. Here is a schematic on how that resistor is tied in the circuit.  Notice the 2-Ohm 25 watt resistor is in series with the motor on the rewind (take-up) mode. I have a tendency to believe if a 4-ohm or maybe an 8 ohm resistor was used, it would give the phase controls a little better head room to play with. I installed a phase control on a CFS pay-out head. (it fit perfectly.) I have not tested it yet, hopefully I'll be able to do that in a few minutes.

| IP: Logged

|

|

|

|

|

|

|

|

Paul G. Thompson

The Weenie Man

Posts: 4718

From: Mount Vernon WA USA

Registered: Nov 2000

|

posted 09-02-2002 11:45 PM

posted 09-02-2002 11:45 PM

Believe me, Steve...it does....I am talking about series-wound motors. I used that trick on desoldering vacuum pumps and other equipment using ad/dc series wound motors while I was in the navy.

| IP: Logged

|

|

Joe Redifer

You need a beating today

Posts: 12859

From: Denver, Colorado

Registered: May 99

|

posted 09-03-2002 02:36 AM

posted 09-03-2002 02:36 AM

OK back on subject here:I do believe this is perhaps a payout/brain problem... more specifically the spring that returns the payout arm. Perhaps it is just too stiff since it is so new. The film needs to tug just a bit harder to make the platter turn at the right speed, and when it does (after wrapping about 3/4 of the way around the brain) it unwraps and the payout arm moves back a touch. Then the cycle repeats again and again. The elevator does not move at all during this. All I know is that the Strong phase control A-3's at my old theater that is now over 10 years old never had problems like this. In fact I think we only had to replace one brain due to a bad LED the entire time I was there. I'd rather spin both decks by hand myself than have a microswitch system. Hey waitaminute that's actually happened with a microswitch system!

| IP: Logged

|

|

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 3 pages: 1 2 3

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

....but it didn't come from Strong International.

....but it didn't come from Strong International.