|

|

This topic comprises 4 pages: 1 2 3 4

|

|

Author

|

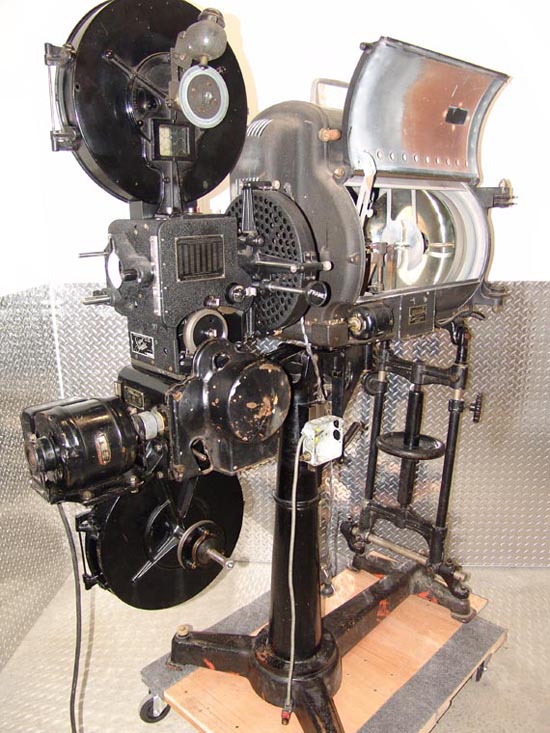

Topic: Super Simplex / RCA 1040 / Peerless Magnarc Restoration

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Will Kutler

Phenomenal Film Handler

Posts: 1506

From: Tucson, AZ, USA

Registered: Feb 2001

|

posted 01-16-2006 11:23 PM

posted 01-16-2006 11:23 PM

On the Supers, take a look at the manuals Forum on FT.

Pay attention to what gears you have, straight bevel or spiral.

Also look at gear wear.

Keep in mind that these Simplexs used hardened steel shafts against a softer cast iron bearing surface. Sometimes dirt, lack of maintenance and just wear will cause lots of scoring. But even if they are scored, a deburr-cleanup will often be enough to get them running again, so long as there is not too much slop between bearing surfaces.

Mark can chime in, but if memory serves me right, shafts could be ordered with different diameters as a corrective remedy. Or, a machine shop might be able to overbore the casting and press in oil-lite bushings...which would also do a lot to decrease the amount of daily oiling. I'v forgotton, but the oil-lite thing might be iffy due to a lack of "meat" around critical areas?

Also pay attention to the shims behing the shutter shaft casting, and if you do remove it, be careful so as to not crack it.

Also, be careful of the nickel plated parts. Those are actually nickel plated brass, and overbuffing will remove the plating.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 4 pages: 1 2 3 4

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic