|

|

This topic comprises 3 pages: 1 2 3

|

|

Author

|

Topic: Dropping Prints!!!!! Help!!!!

|

|

|

Manny Montes

Master Film Handler

Posts: 270

From: United States

Registered: Feb 2010

|

posted 03-05-2010 11:28 PM

posted 03-05-2010 11:28 PM

Take a clamp, put the long side and push it from the outside of the print to the center, then place the short end (with the knob) in the centerpiece and connect to the other side of the clamp. Kind of confusing I know

I've also used a "Print Donut" and cart, where its a little cart with a flat surface about as big as a print, the donut is just a big disc made out of some material thats pretty strong (wood perhaps?), it has holes in the middle so the centerpiece can go on, you simply slide that under the centerpiece for the last show, thread as normal and move.

For more stability no matter which way you choose I'd always Z-wrap a print before you move it. For the last show simply thread the elevator (yo-yo, dancer, etc) from the lower guide roller to the top 2 rollers on the elevator (left to right) then to the bottom left roller, then to the bottom right roller on the elevator. So instead of making a "W" shape, the film should make a "Z" shape. This causes the print to wind tighter.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Monte L Fullmer

Film God

Posts: 8367

From: Nampa, Idaho, USA

Registered: Nov 2004

|

posted 03-06-2010 09:26 PM

posted 03-06-2010 09:26 PM

For the interested and curious:

Supplies needed for construction:

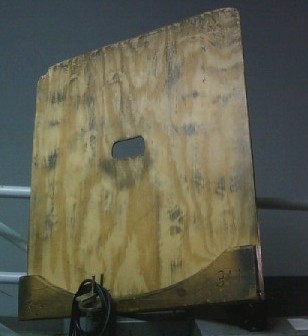

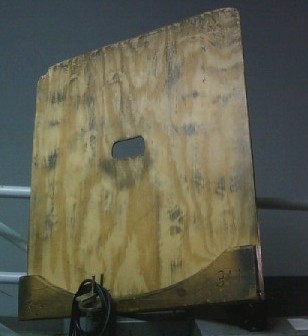

1-36"x32"x1/4" sheet plywood preferably one side finished (or what's called "sand shop" grade)

1-2x6x32 for the end piece

1.5" drywall screws and optional construction adhesive to glue the piece down and add screws right after the piece is glued down.

the 2x6 has to have that circular cutout so the print can have something to lay against and to help keep the print centered on the board. Best wood would be redwood for that end piece since its lighter and easier to cut if you have to use a jig saw instead of a band saw.

The open hand grab in the middle is 3 x 6 cutout and about in the middle, but towards a bit to the front nose piece so when you carry it on you side, the end piece isn't hitting the floor.

The nose piece of the board needs to be trimmed to a taper so it can scoot under the prints better. Plus, round the front nose corners to help prevent splintering, even though, after many years of use, the nose end will still splinter out some.

An optional usage is to adhere duct tape to the sides of the board to prevent side splintering, but if you do a good sanding job on the sides to a good finish, then the splintering will be extremely rare.

Some picts of our board we made back in 1992 and still doing great even though it's showing it's age and I might have to build another one down the road:

Also, you can make a 3ft square board for those larger prints, esp the ones that hits over 150m and even up to 180 plus minutes.

Also, there is a variant to this board design for those who have solid brain platters, and that is to make the board the 3ft square, but cut out from the front edge to a bit past the middle of the board, an opening the same width of the brain so you can still slide the board under the print, and lift up the print over the brain.

Thx and good luck all -Monte

| IP: Logged

|

|

|

|

|

|

Monte L Fullmer

Film God

Posts: 8367

From: Nampa, Idaho, USA

Registered: Nov 2004

|

posted 03-07-2010 03:21 AM

posted 03-07-2010 03:21 AM

I can see your point there, Chris and it would be a nice advantage for just the one cinema as an in-house print mover, (to do a circular cut, would be to use a pencil and string to draw the needed circle, and jig saw to cut the circle out of the plywood. Then a belt sander to smooth the edges to make such a device..) but with this design we can move any film from any other make of platter unit - be it STRONG, Christie, ORC, et.al. , since we do tonnage of print circuits from other theatres..

Sure beats the 6k reel transfers. But, once in a while, we have to do the 6k transfers since some theatres are a little gamey on doing board transfers and want their platter equipment to remain on their premises...but that's a rare situation since I've made prior arrangements to show these other theatres the advantages of this method of circuiting prints.

-monte

| IP: Logged

|

|

|

|

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 3 pages: 1 2 3

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

![[Mad]](mad.gif)

![[Wink]](wink.gif)