|

Author

|

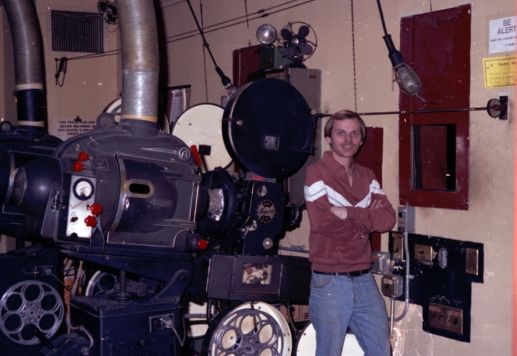

Topic: Simplex E-7 Collectors

|

|

|

|

|

|

|

|

|

Monte L Fullmer

Film God

Posts: 8367

From: Nampa, Idaho, USA

Registered: Nov 2004

|

posted 08-08-2014 03:05 AM

posted 08-08-2014 03:05 AM

A former company I used to work for took over a single palace house that was closed up for years.

Booth had E-7's, Simplex Mag penthouses and Enarc lamphouses. My task was to convert the booth to be ready for xenon and platter. Thus, I took out the No.2 machine for the platter and No.1 machine to be cleaned up and converted to LED reverse scan.

Both projectors had noisy intermittents, yet found parts in the location to do one rebuild.

Being the old taper pin starwheel shafts, I dismantled the assembly and cleaned out all the goo that resided in the case. The starwheel was in bad shape due to a bad cam pin. Replaced both with the new found parts along with reversing the sprocket to use the other side.

I fine tuned in the assembly to where one can feel the pin enter into the starwheel at the right moment, tightened it all up, filled it with oil and let it run in for a while. Ran film through that thing and it was ghostly quiet for film to pass through an E-7 after that rebuild.

Owner was impressed along with the manager on how quiet that machine ran - quieter than a PR-1050 at the other locations..

Two weeks later, a high school booth clown made his loops too small causing a splice break which the upper sprocket took the break en to wrap it good around the upper sprocket to stop it and to shred out the oblique gear .. and had to rebuild that E-7 again with parts that were still on location.

He was told on how the loops supposed to look like, but he didn't care - he lost his job that same day.

-Monte

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

![[thumbsup]](graemlins/thumbsup.gif)

![[Smile]](smile.gif)